Once radiation losses are reduced through the use of low-E coatings, convection and conduction losses controlled through the use of gas fills, and conduction heat losses around the edge of the glazed unit reduced via insulating spacers, window frames represent the next potential weak link in the energy efficiency chain. Recognizing that one-third of the overall window is the frame and sash, it is important that they be made to minimize conductive heat loss.

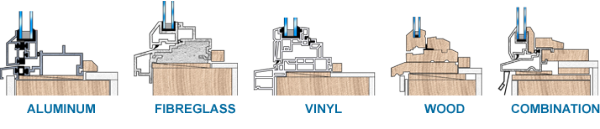

Good frames can be made from any of the materials commonly used such as wood, aluminum, vinyl, fibreglass and so on, as long as the weaknesses of each are recognized and compensated for. For example, wood frames with an aluminum or vinyl exterior cladding reduce maintenance; aluminum frames with a wide continuous thermal break reduce conductive heat loss; or vinyl frames reinforced with metal add strength.

Frames can also have a significant impact on solar gain. Stronger materials allow the frame and sash to be narrower. This results in more glass area, which increases solar gain and decreases heat loss through conductivity. These are called low profile frames and, to date, have achieved the best energy performance ratings.